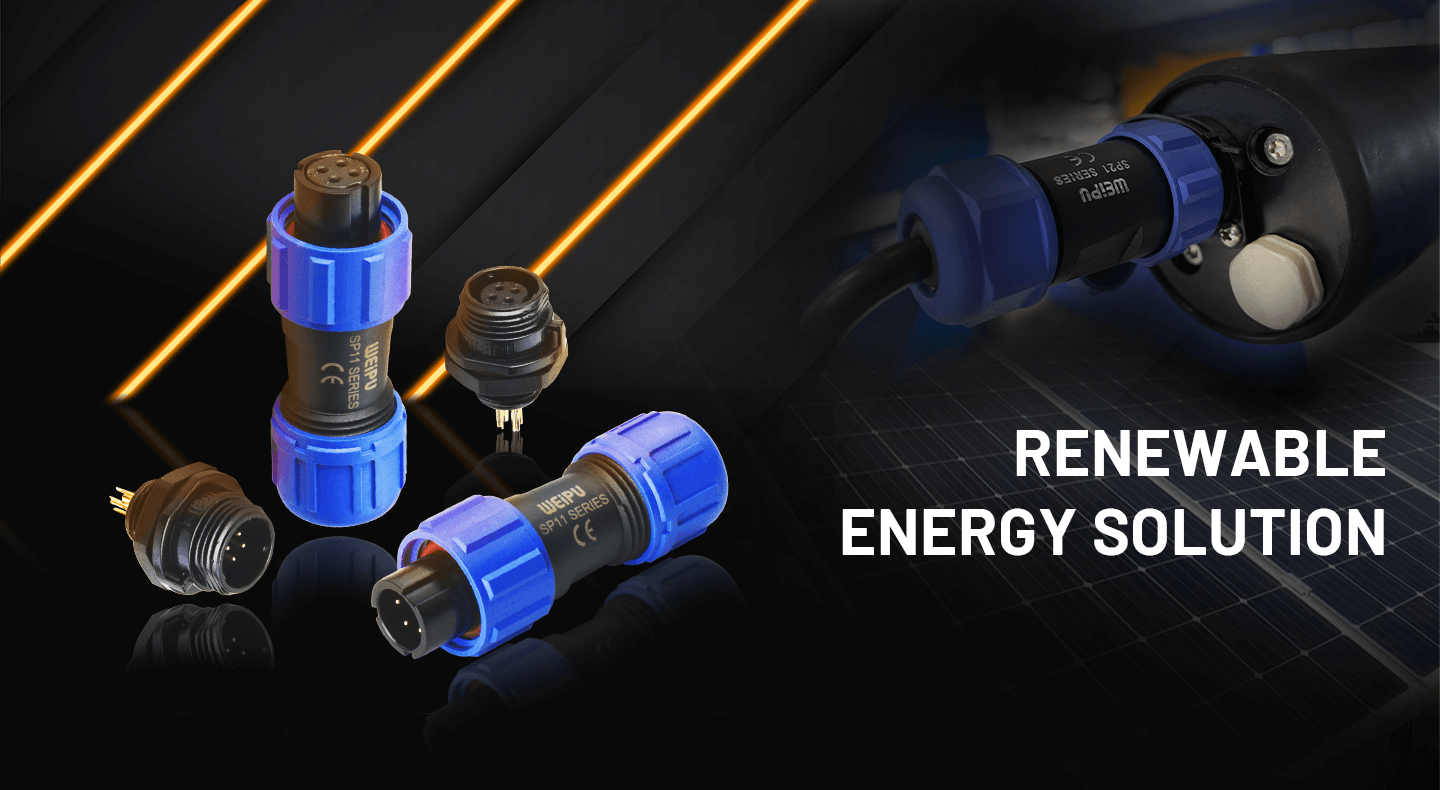

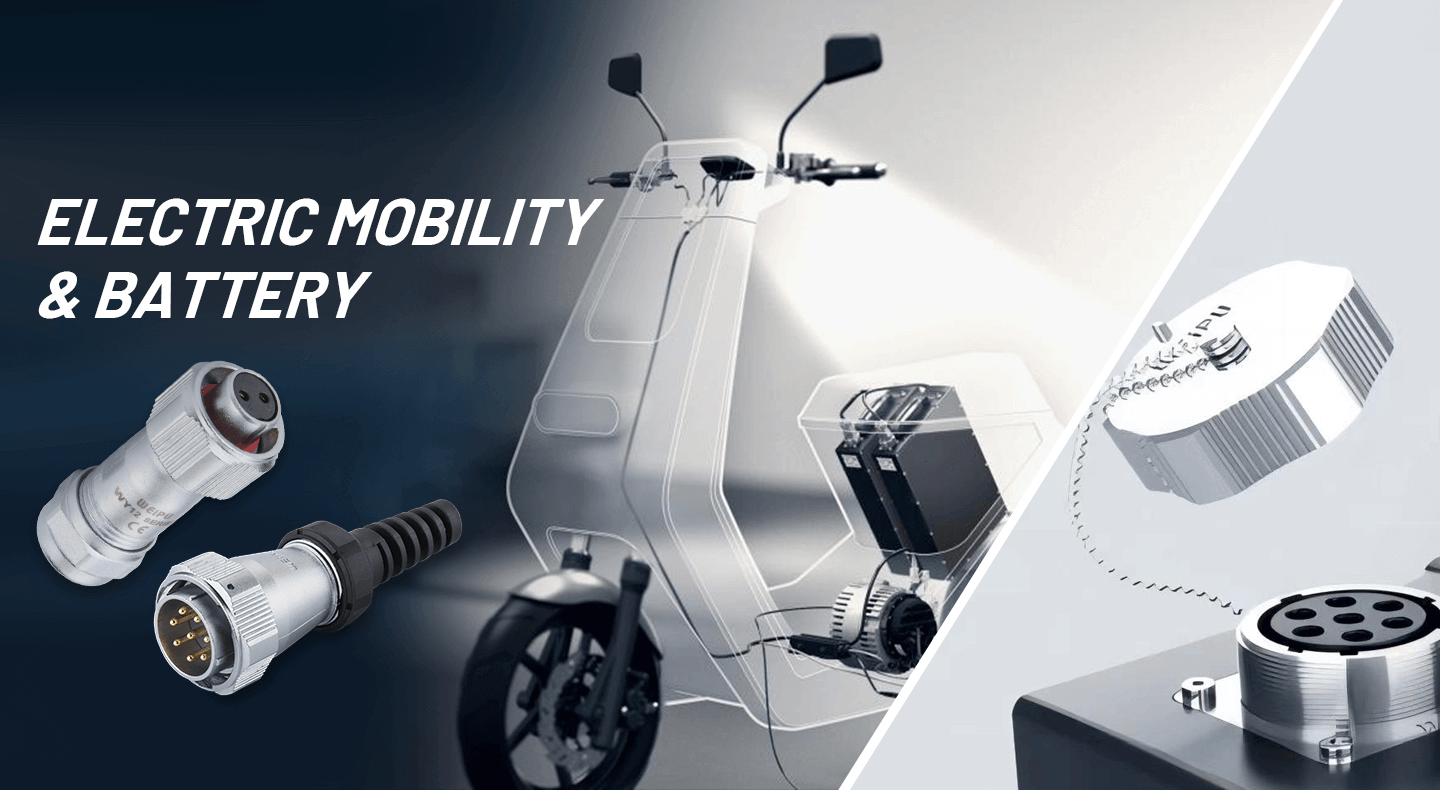

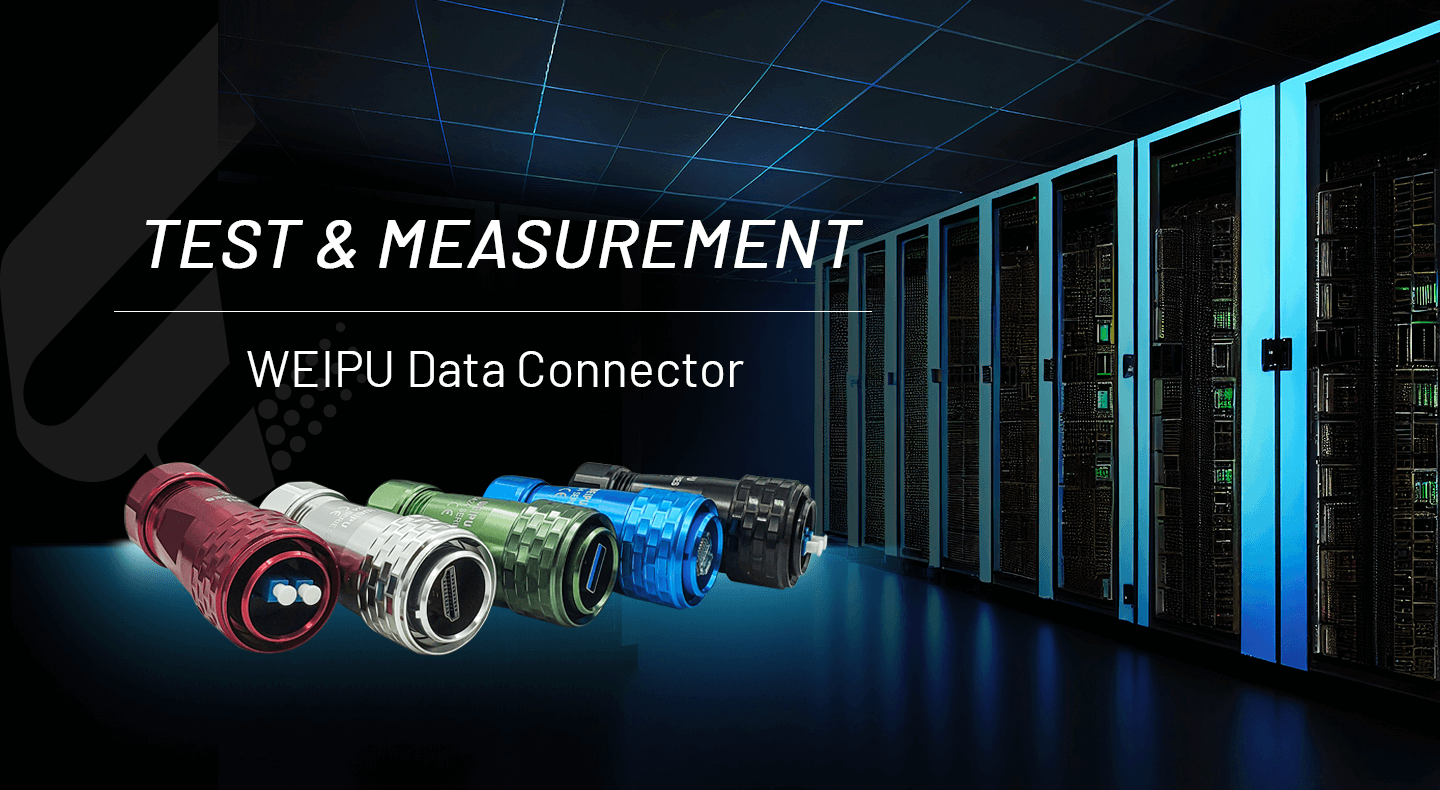

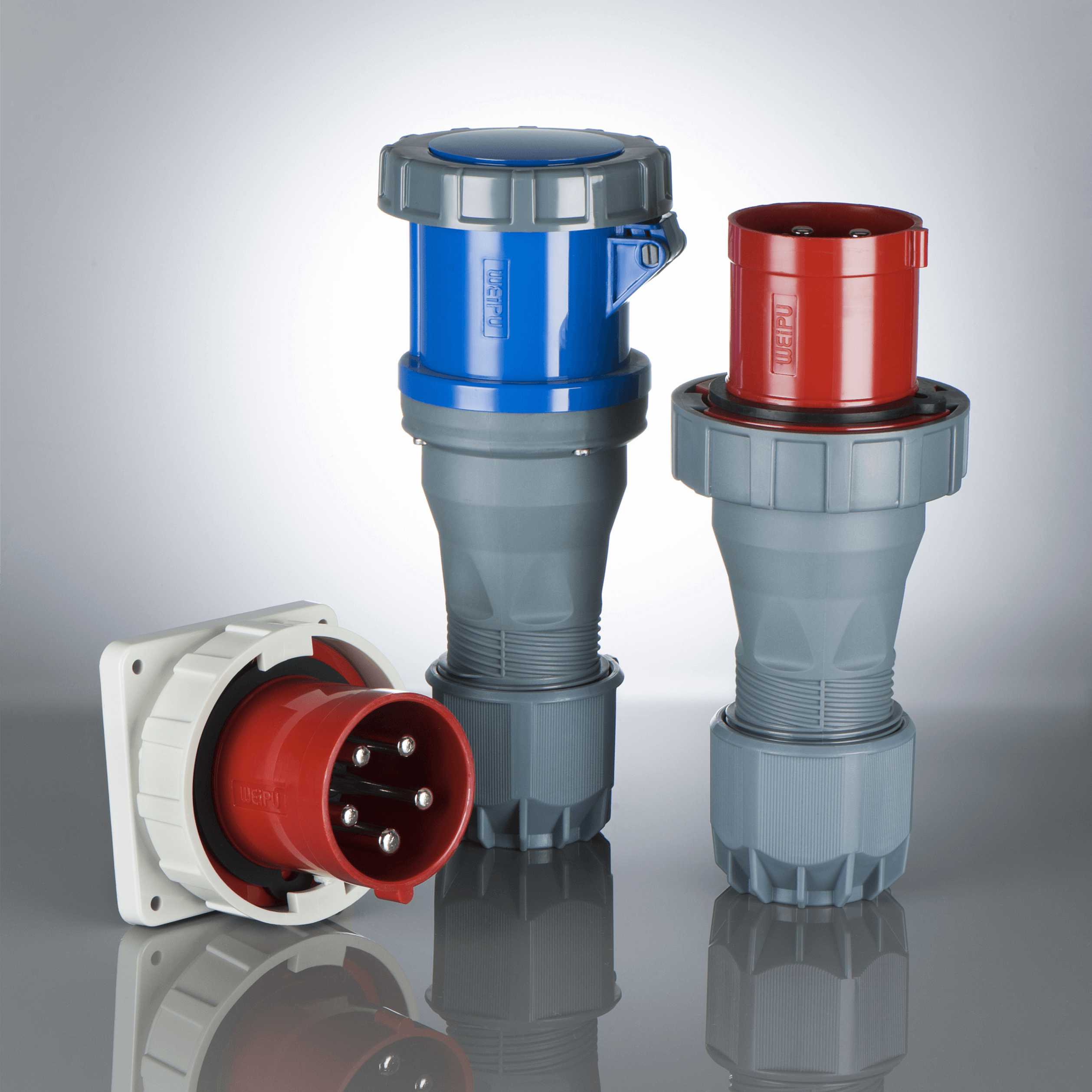

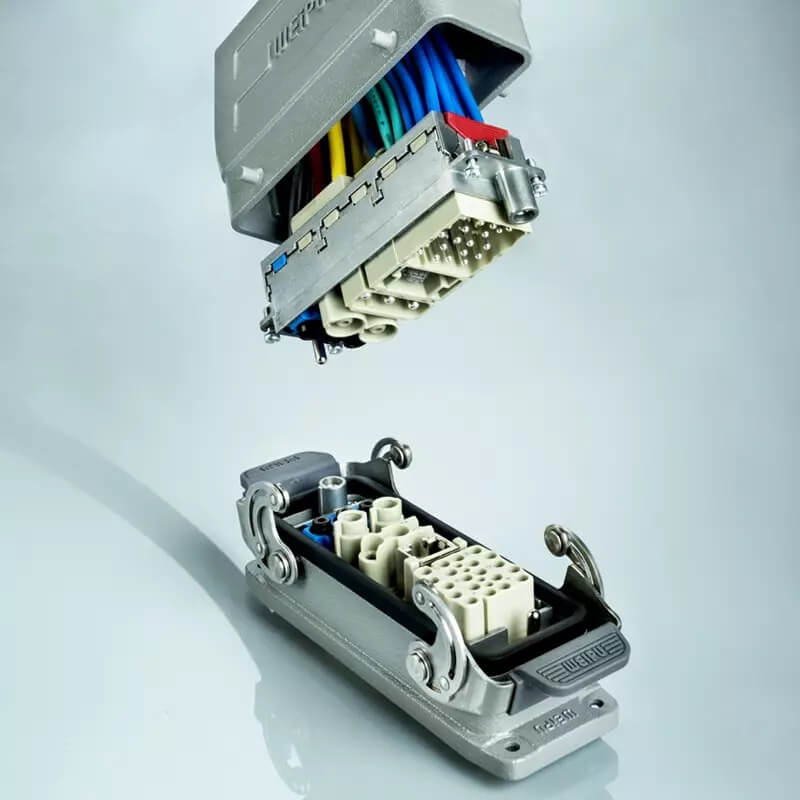

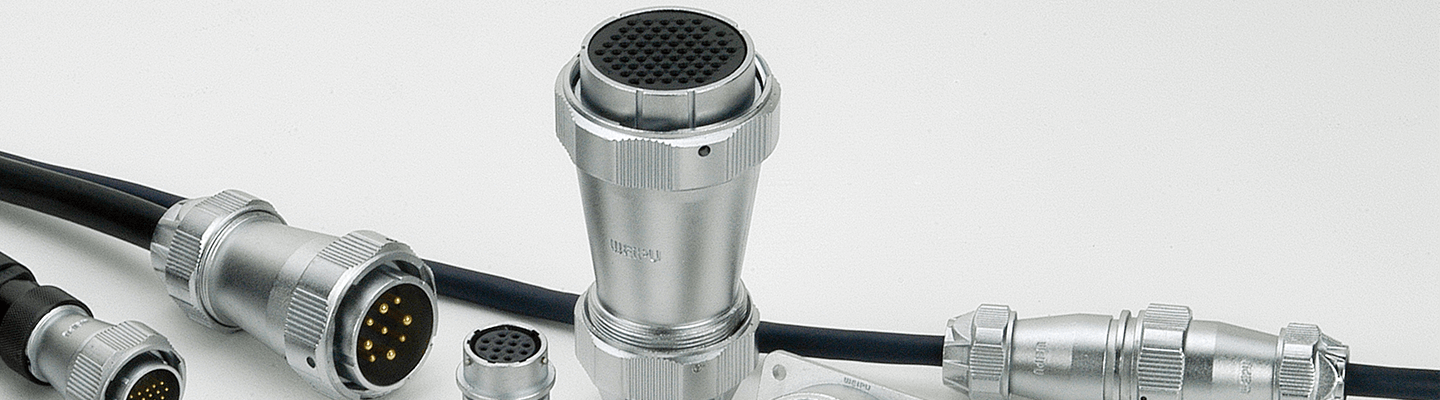

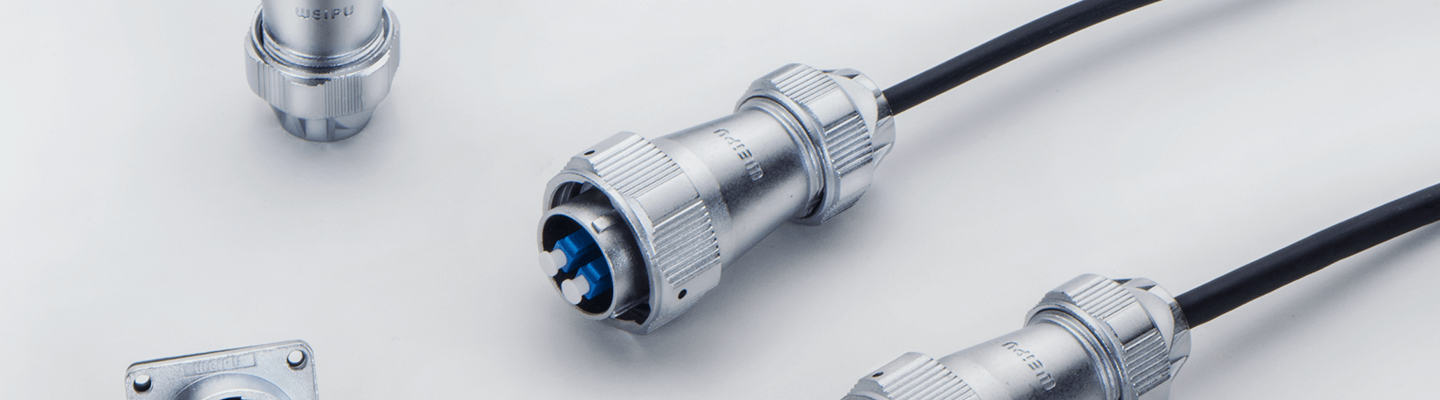

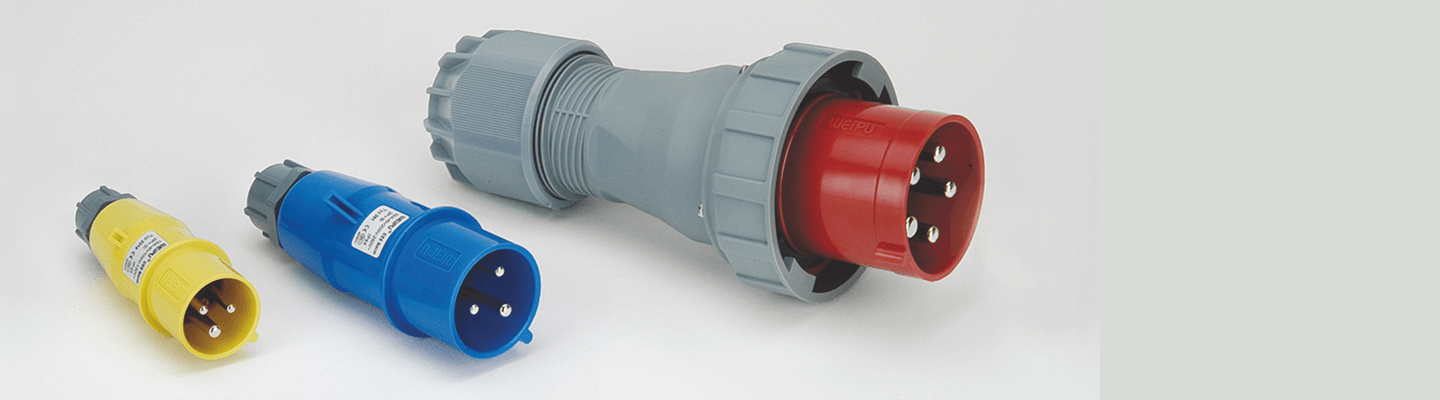

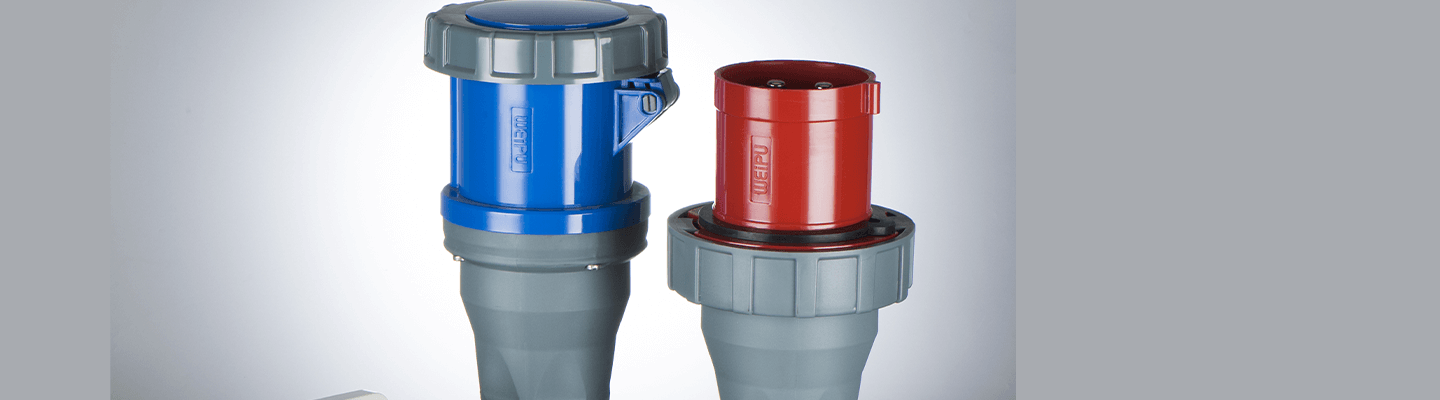

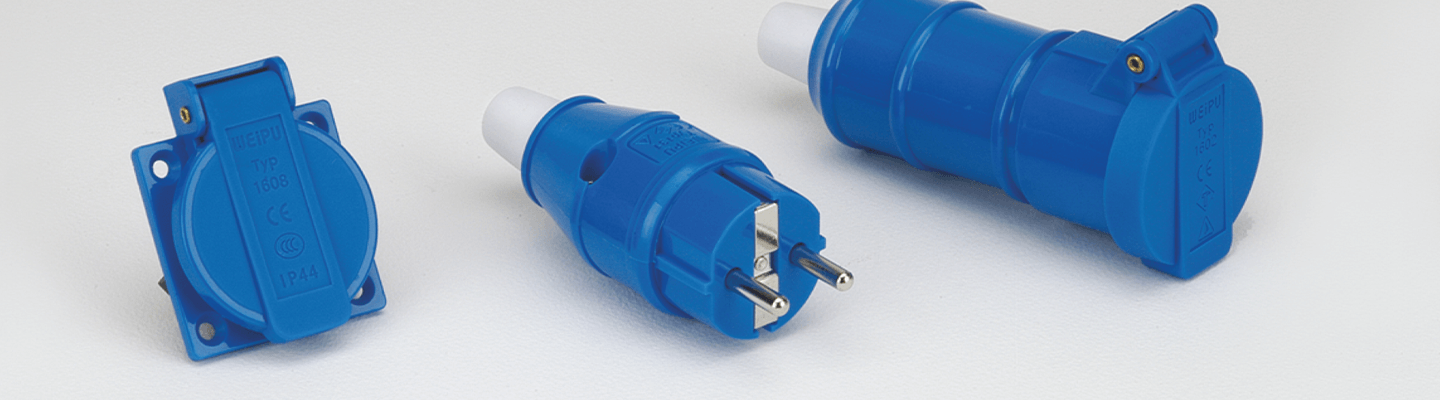

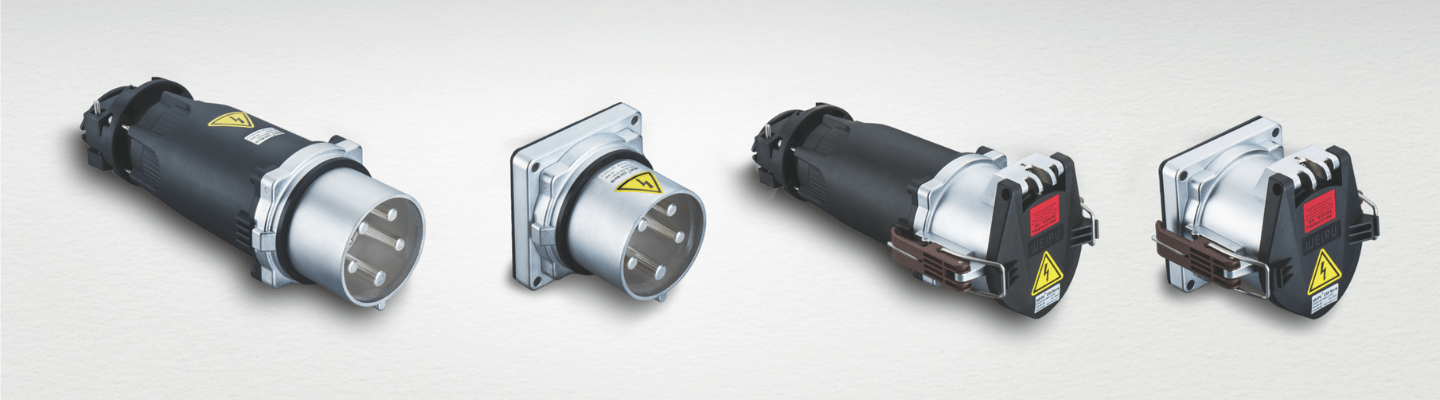

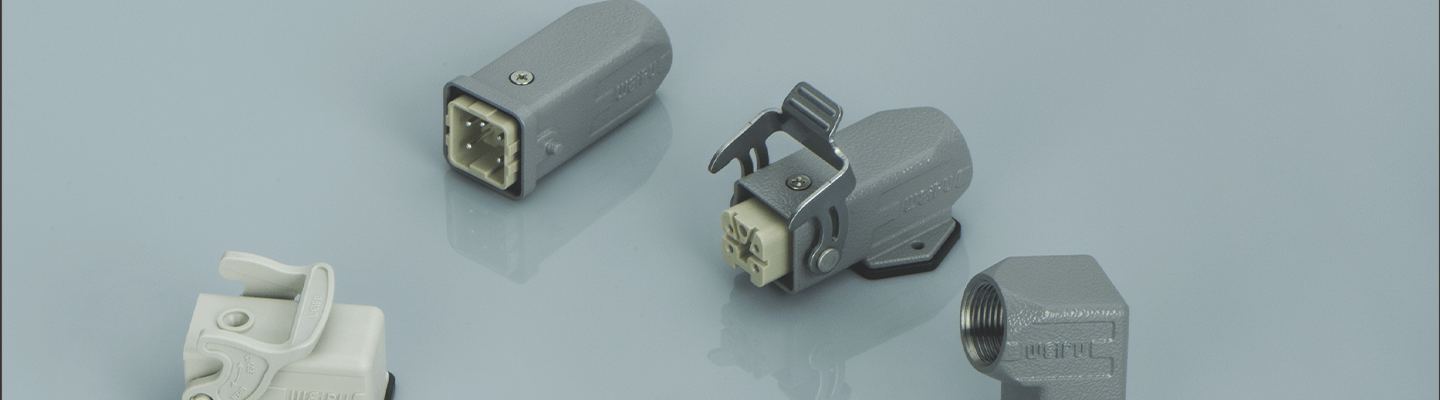

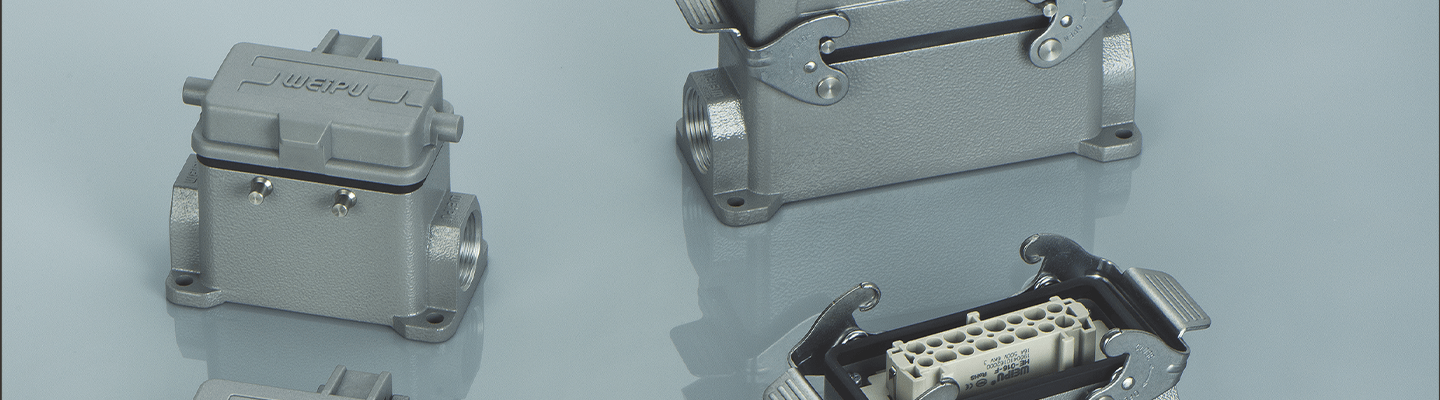

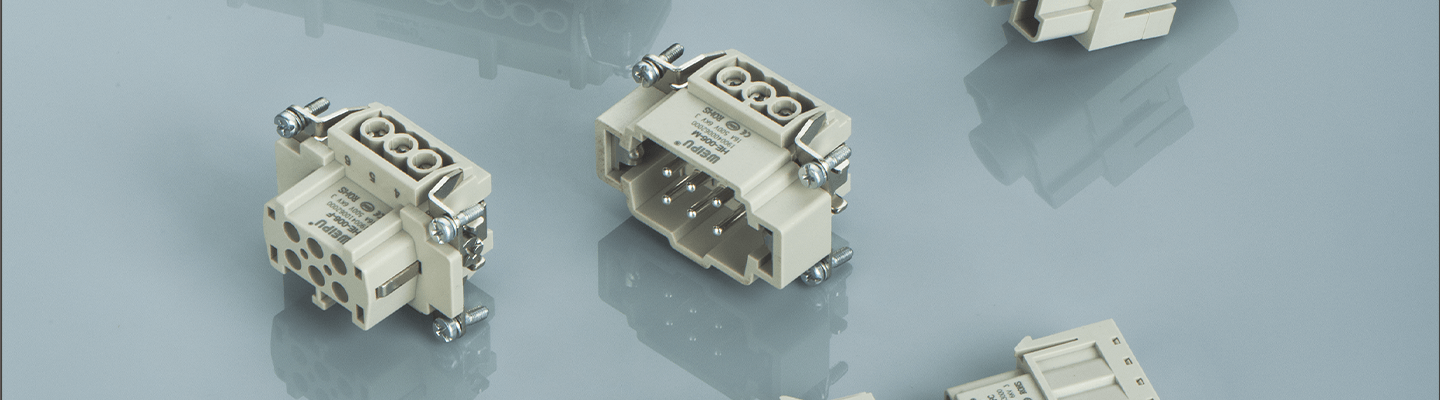

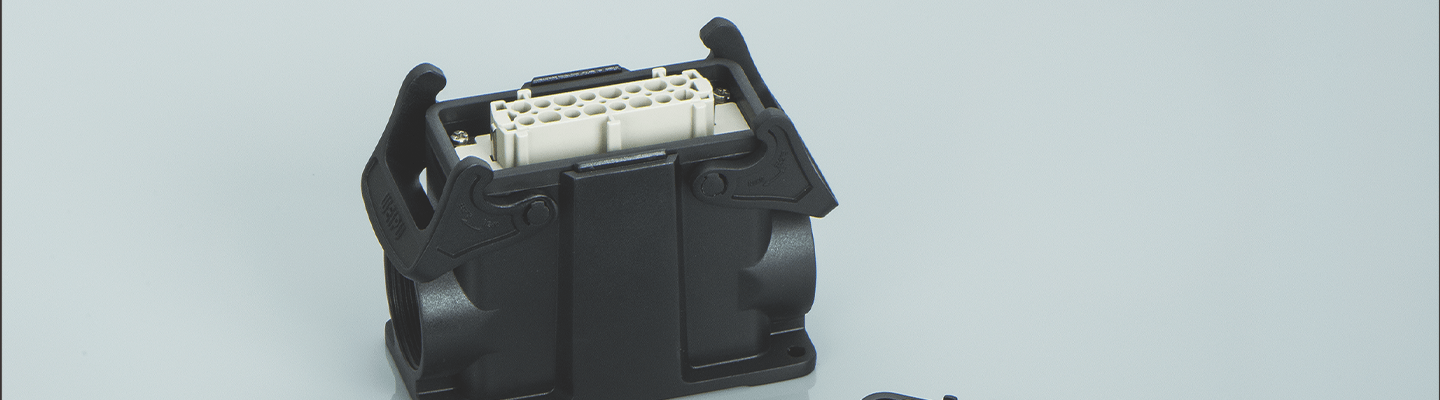

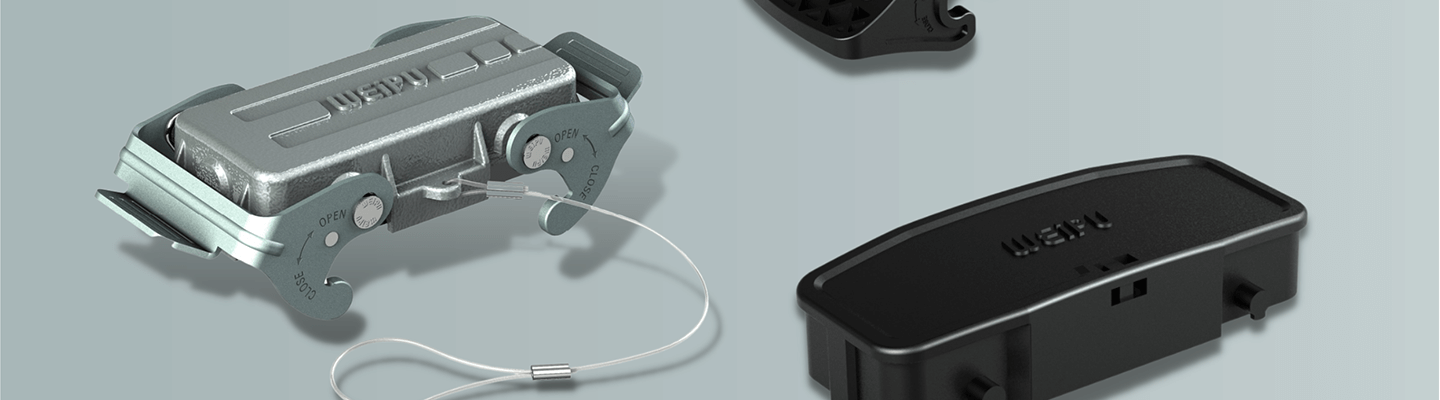

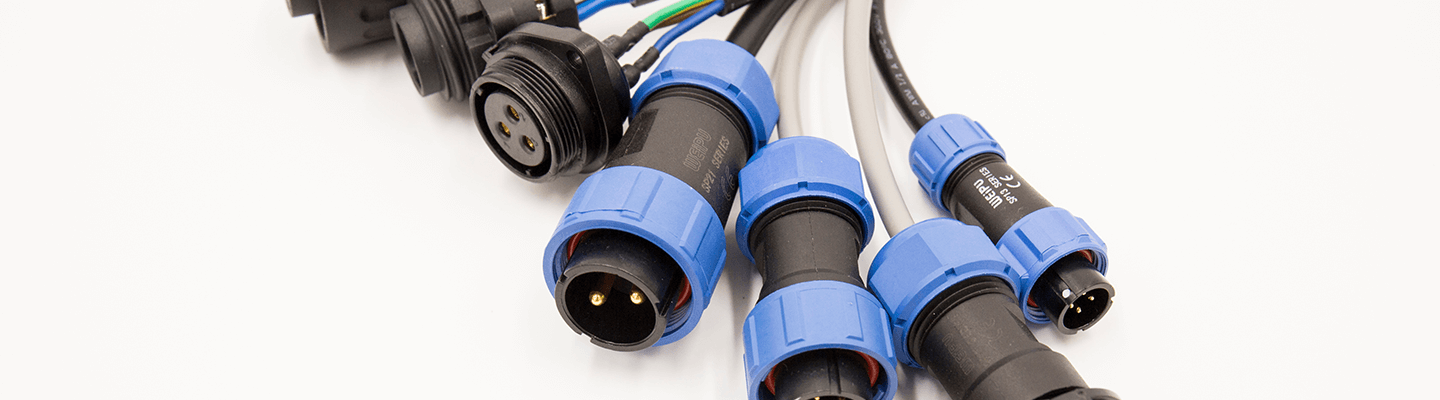

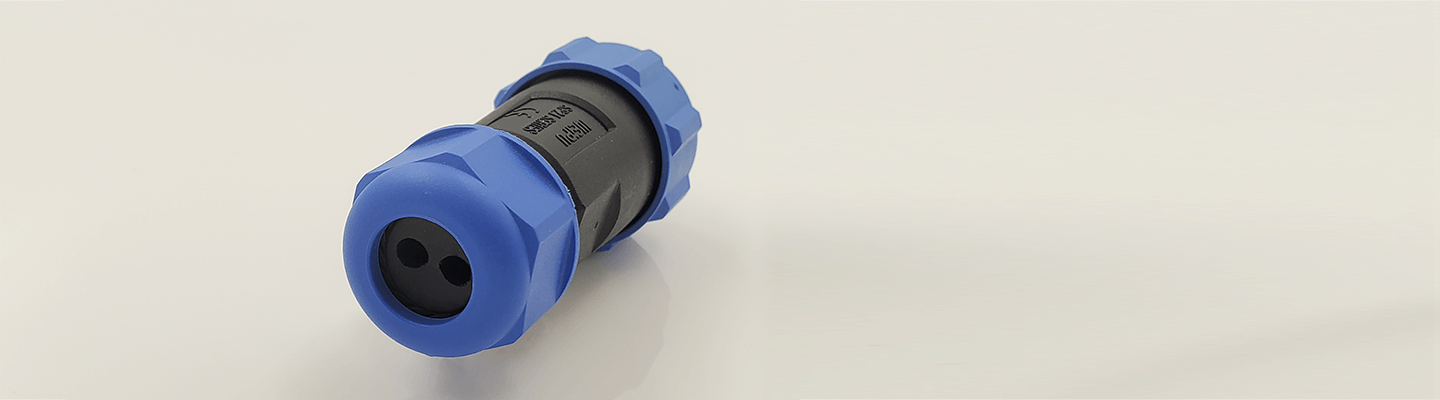

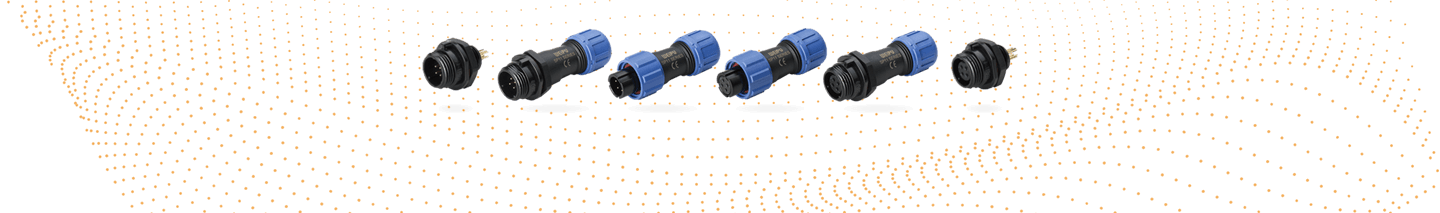

With nearly 30 years of experience in the industry, we specialize in waterproof connectors that can withstand even the harshest and most challenging environments. Our connectors are not only waterproof but also feature a solid and reliable design, ensuring that your connections stay secure and dependable whether on data, power, or signal connection across a variety of industries.