News & Event

Technical Articles

2023.01.24

The Science Behind Waterproofing: Inside a Connector’s Design

Waterproof connectors play a crucial role in ensuring the reliability and durability of electronic devices and systems, especially in challenging environments where exposure to moisture, water, and dust is a constant threat. In this exploration, we delve into the science behind the design of waterproof connectors, understanding the techniques that make them resistant to water and dust, and the key elements that contribute to their effectiveness.

Sealing Techniques:

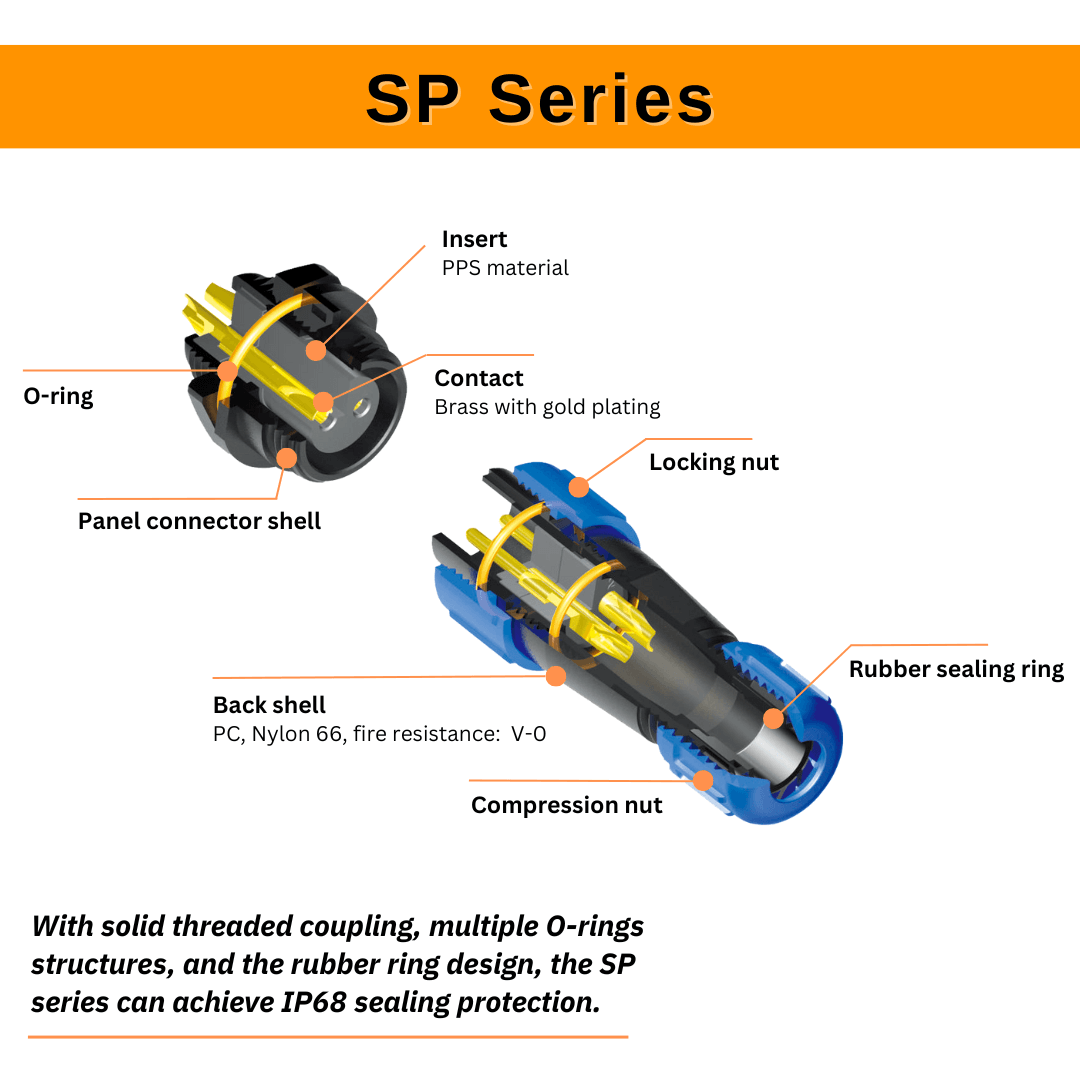

- O-Ring Seals: Many waterproof connectors employ O-ring seals made of resilient materials like silicone or rubber. These seals are strategically placed to prevent water ingress, forming a tight barrier around connection points.

- Compression Seals: Some connectors use compression seals that tighten around the cable or mating interface when the connector is assembled, creating a secure, watertight enclosure.

For example, below is the structure of the WEIPU SP series and it illustrates the main elements that make it achieve IP68 protection.

Material Selection:

- Housing Materials: The choice of materials for connector housing is critical. Waterproof connectors often use materials like plastic, metal alloys, or even specialized materials like PPS (Polyphenylene Sulfide) that offer high resistance to water and dust.

- Coating Technologies: Connectors may be coated with protective layers, such as nanocoatings or epoxy resins, providing an additional shield against moisture and contaminants.

IP Rating and Ingress Protection:

- IP Standards: The Ingress Protection (IP) rating system classifies the degree of protection a connector offers against the intrusion of solids and liquids. For example, the WEIPU SP series has an IP68 protection rating and has been tested under 10 meters of water for one week.

- Testing Protocols: Manufacturers subject their connectors to rigorous testing procedures to ensure they meet or exceed IP standards, guaranteeing reliable performance in real-world conditions.

Connector Design:

- Threaded Coupling: Connectors such as the WEIPU SP series with threaded coupling enhance sealing by providing a secure and tight fit between mating halves, minimizing the chances of water or dust penetration.

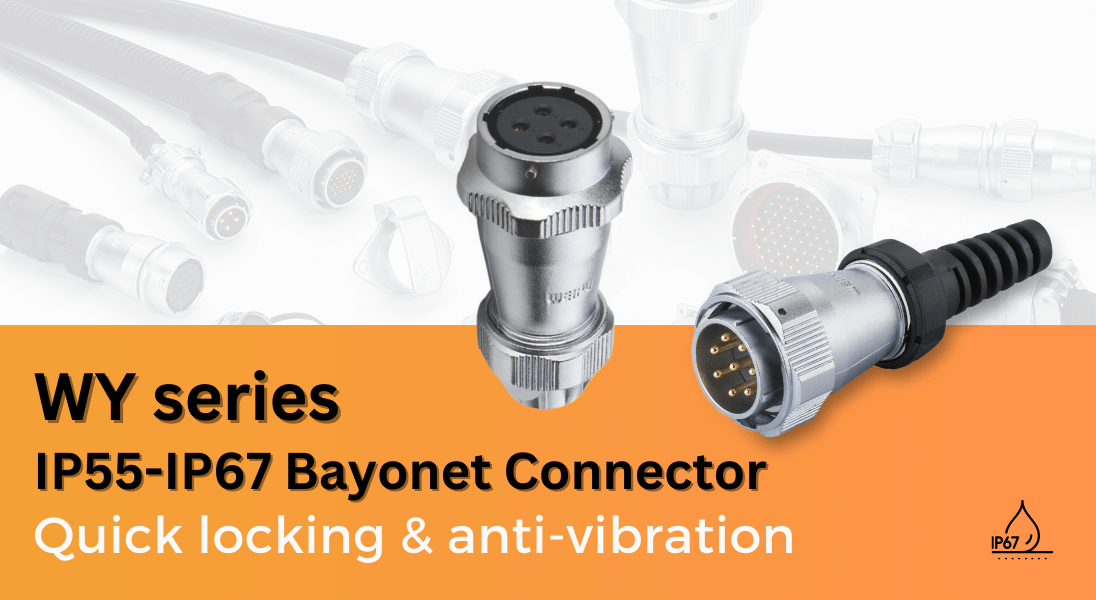

- Bayonet Coupling: Series like WEIPU SY, featuring bayonet coupling, offer a quick and secure locking mechanism, enhancing resistance to vibration and environmental stress.

Additional Protective Features:

- Sealing Caps: Many waterproof connectors, including certain WEIPU series, come equipped with sealing caps that provide extra protection when the connector is not in use.

- UV Resistance: Connectors designed for outdoor use often incorporate materials with UV resistance, safeguarding against the deteriorating effects of prolonged exposure to sunlight.

Conclusion: The science behind waterproof connectors involves a combination of innovative design, precise engineering, and the use of advanced materials. By understanding the techniques employed, including sealing mechanisms, material choices, and protective features, we gain insight into how these connectors ensure the integrity of electronic systems in the face of harsh environmental conditions. The ongoing evolution of waterproof connector technology continues to contribute to the reliability and longevity of electronic devices across various industries.

Professional Waterproof Connector